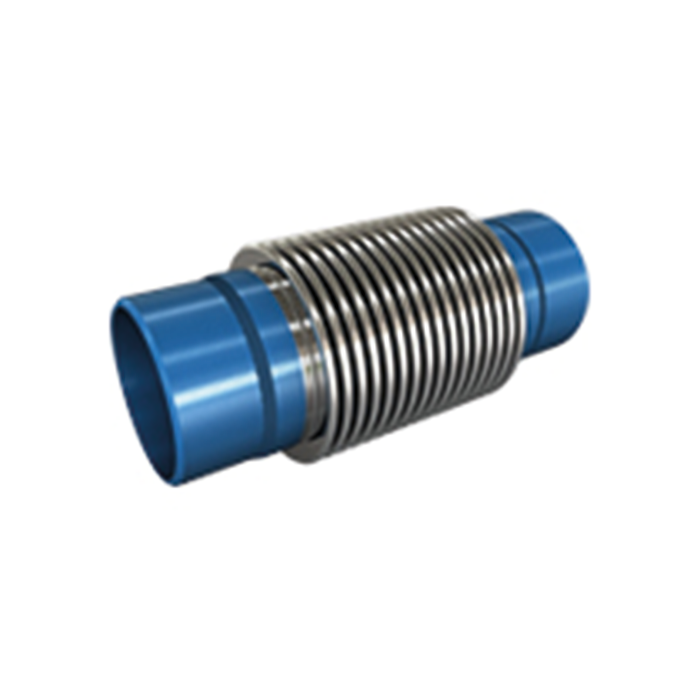

KRS-13 PN 16

Weld End Expansion

Weld-neck expansion joints are a type of axial expansion joint designed to absorb thermal expansion occurring in pipelines in the axial direction. These components are particularly preferred in high-pressure and high-temperature applications, contributing to the long-lasting and safe operation of the system.

In systems engineering, pipelines are typically divided into different expansion zones, separated from each other by fixed points. Thanks to this structural solution, thermal movement in each expansion zone is controlled solely by the axial expansion joint placed within that specific zone.

The weld-neck design ensures a stronger and leak-proof connection to the pipeline. This enhances durability, especially in environments with vibrations or significant temperature differences. The secure welded connection provides more stable load transfer within the system and minimizes the risk of loosening or deformation at connection points.

Technical Information

Standard Production : AISI 321 (DIN 1.4541)

Special Production : AISI 304 (DIN 1.4541), AISI 309 (DIN 1.4828), AISI 316 (DIN 1.4401), AISI 316 ti (DIN 1.4571) etc

Design Pressure : 16 BAR

Design Temperature : – 196 + 550 C

Standard Weldend : Rst 37-2 (DIN 1.0038)

Special Weldend : Stainless Steel etc.

Standard Liner : AISI 321 (DIN 1.4541)

Special Liner : AISI 304 (DIN 1.4541), AISI 309 (DIN 1.4828), AISI 316 (DIN 1.4401), AISI 316 ti (DIN 1.4571) etc

Technical Drawing

Applications

To absorb axial expansions, reduce stress and noise in the system, all machines, all motors, all pumps, industrial applications, exhaust applications, gas and water lines, drinking water lines, etc.

Paint Information

Flanges between DN 25–DN 300 are cadmium plated. For sizes DN 300 and above, specially painted flanges resistant to corrosion are used. It offers high durability and long-lasting use for industrial systems.

Special Note

If requested, the design temperature can be increased to +950°C. Contact us for special requests. Flange tables are in the technical tables section. Product weights have a tolerance of ±10%. Liner is recommended for abrasive fluids.

| Diameter (DN) | Length (L) (mm) |

Liner Diameter Ø Di (mm) |

Outer Diameter Ø Do (mm) |

Movement +/- AX (mm) |

Spring Rate AX (N/mm) |

Bellows Effective Area KEA (cm²) |

Pipe Diameter Ø D x s (mm) |

Approx. Weight (Kg) |

|---|---|---|---|---|---|---|---|---|

| 25 | 180 | 25 | 45 | 11 | 43 | 12 | 33,7 x 3,25 | 0,50 |

| 32 | 180 | 32 | 53 | 11 | 43 | 13 | 42,4 x 3,25 | 0,60 |

| 40 | 180 | 38 | 62 | 14 | 65 | 24 | 48,3 x 3,25 | 0,70 |

| 50 | 200 | 50 | 77 | 18 | 85 | 34 | 60,3 x 3,65 | 1,10 |

| 65 | 220 | 65 | 97 | 19 | 100 | 58 | 76,1 x 3,65 | 1,60 |

| 80 | 220 | 77 | 115 | 21 | 77 | 82 | 88,9 x 4,05 | 2,00 |

| 100 | 230 | 100 | 146 | 21 | 92 | 134 | 114,3 x 4,50 | 2,90 |

| 125 | 260 | 125 | 170 | 26 | 69 | 192 | 139,7 x 4,85 | 3,50 |

| 150 | 290 | 150 | 199 | 26 | 133 | 265 | 165,1 x 4,85 | 4,80 |

| 200 | 290 | 200 | 254 | 36 | 162 | 442 | 219,1 x 6,30 | 8,10 |

| 250 | 290 | 253 | 315 | 25 | 419 | 683 | 273,0 x 6,30 | 9,10 |

| 300 | 400 | 304 | 393 | 26 | 524 | 1020 | 323,9 x 7,10 | 18,00 |

| 350 | 400 | 330 | 415 | 26 | 573 | 1203 | 355,6 x 8,00 | 28,00 |

| 400 | 400 | 384 | 475 | 25 | 650 | 1536 | 406,4 x 8,00 | 32,00 |

| 450 | 400 | 434 | 525 | 25 | 739 | 1895 | 457,0 x 8,00 | 32,00 |

| 500 | 400 | 484 | 568 | 25 | 807 | 2271 | 508,0 x 8,00 | 41,00 |